Velocette Engine Work

Introduction

Velocette Motorcycle Repairs & Engine Rebuilds – Berwick-upon-Tweed

Running a Velocette? I offer full engine rebuilds, precision machining, and specialist repairs - all carried out in my Northumberland workshop using over 50 years of experience and genuine parts.

About

For 25 years I ran my own engineering company in Derbyshire, Materials Handling Products Ltd, specialising in spillage control and wear resistance for the quarrying industry. We manufactured rubber screens for grading stone; if you travel by rail, most of the track ballast will have been graded through our screens. I am a Fellow and past President of the Materials Handling Engineers Association, and a past President of the International Solids Handling Advisory Board, set up to advise government on materials handling matters.

When I retired in 2016, I moved back to Northumberland and opened a workshop in Berwick-upon-Tweed. I set up Design and Prototype to return to my early interest in engines and machining. I now specialise in Velocette motorcycle repair and engine rebuilds, having run Velocettes myself for over 50 years. Over that time I’ve built up a clear understanding of the typical issues these engines develop and the best way to deal with them. I also manufacture Velocette tools, components and usability improvements, along with machining work for other classic motorcycle engines. With turning, milling and welding facilities, I can take on a wide range of engineering and repair tasks.

Earlier in my career, I began as a student apprentice at Rolls Royce Aero Engines in Derby, one of the finest engineering environments of its day. I completed several physics and engineering courses, though I always preferred practical work. I spent time in the motor racing industry building F5000 V8 engines in Derby, worked in the machine shop at Cosworth Engineering in Northampton, and rebuilt a vintage Birdcage Maserati for the owner of JCB. The car later achieved championship success and was sold last year in America for over $6M. My pay at the time, in 1971, was about £50 a week.

I am now Chairman of the Northumbrian branch of the Velocette Owners Club and continue to provide technical advice and support to its members, particularly on Velocette maintenance, repairs and engine work.

Services

Engine work on ‘M’ Series Velocette Engines

I have considerable experience in re-furbishing Velocette Viper and Venom engines.

My expertise includes:-

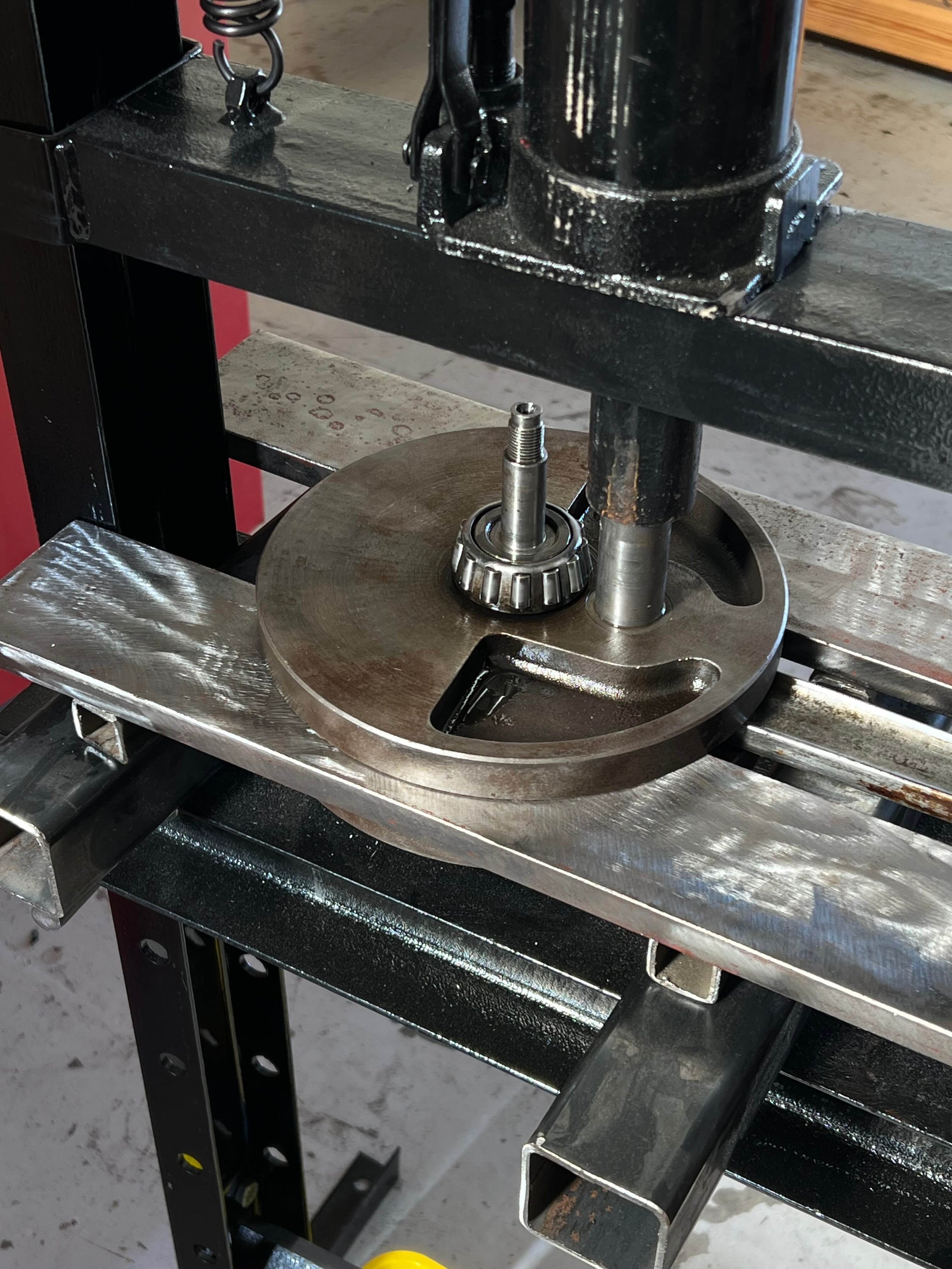

🔧 Big End Replacement

🔧 Main Bearing Replacement

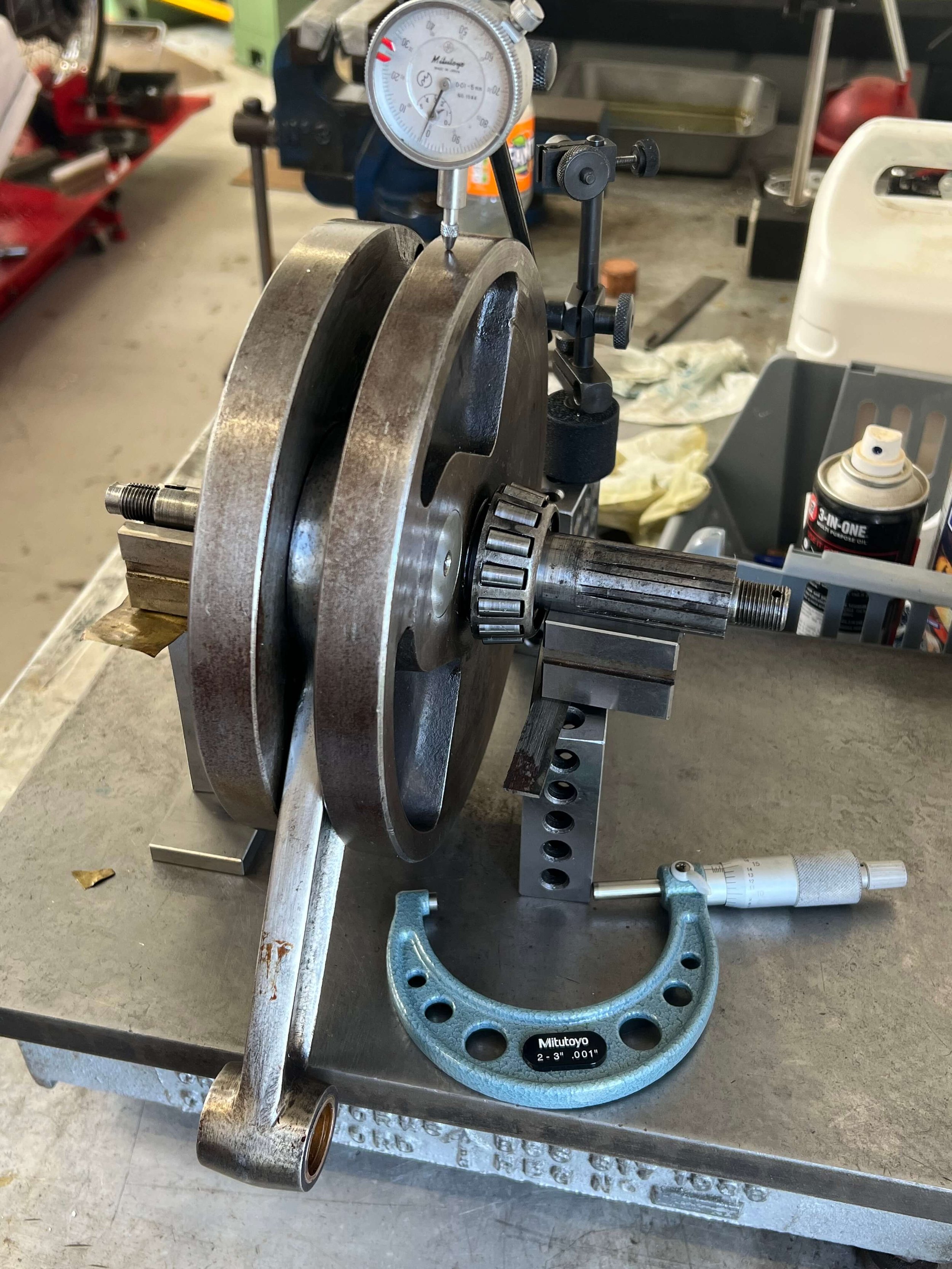

🔧 Crankshaft Alignment

🔧 Crankcase Pre-load Set-up

🔧 Small End Replacement

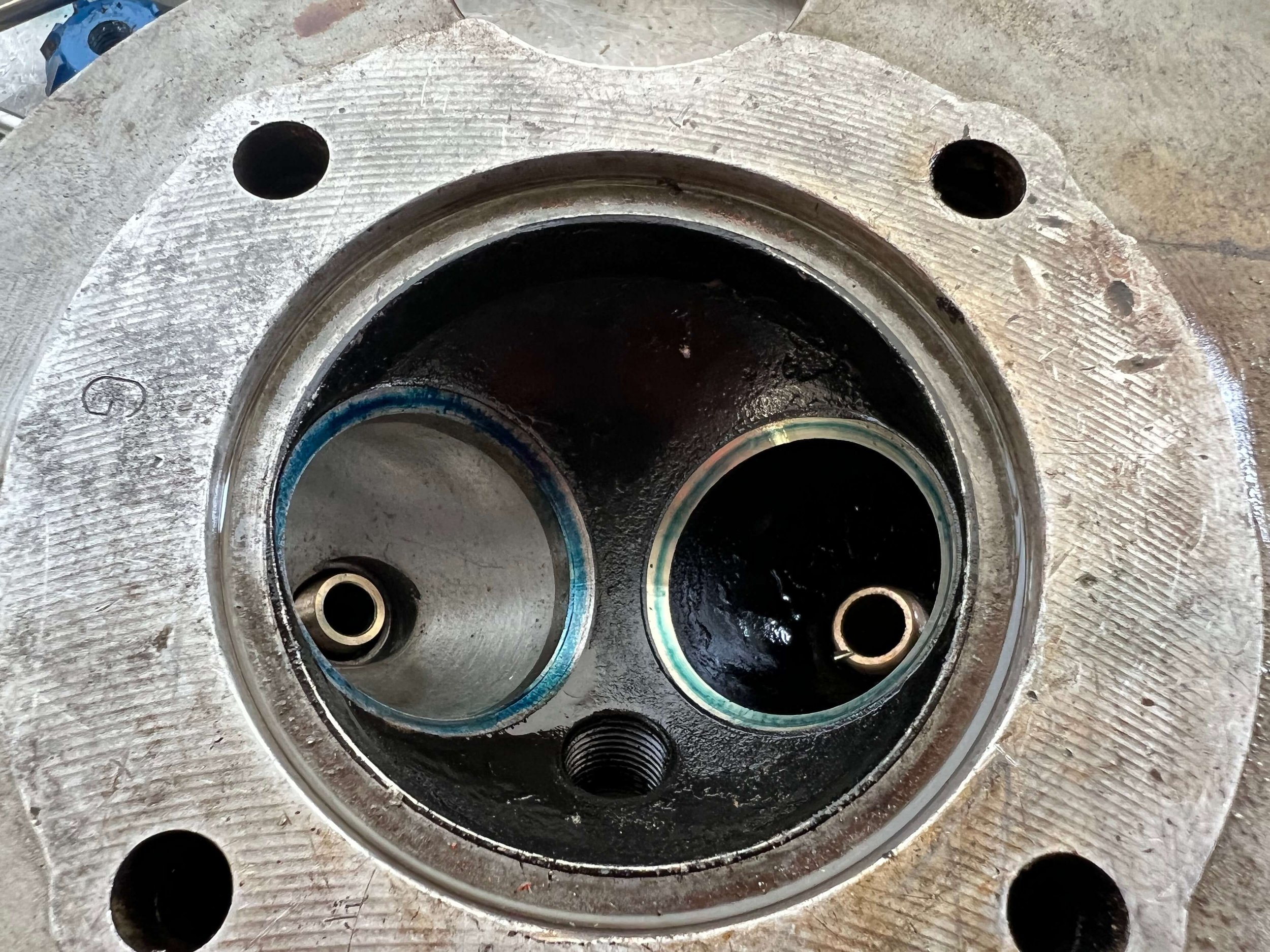

🔧 Valve Guide Replacement and Reaming

🔧 Valve Seat Re-cutting

🔧 Valve Lapping and Assembly

🔧 Valve Spring Replacement

🔧 Valve Timing

🔧 Oil Pump Drive Worm Modification

I only use genuine parts, preserving the authenticity of your Velocette heritage.

To ensure your engine's safe journey, I can offer the option of sending a custom-made wooden case for transportation of the assembled bottom end and head.

Get in touch via email or phone to discuss your requirements.