Innovative Workshop Equipment for Furniture Makers

The Engineer's Workshop: Bridging Gaps with Custom Equipment

My working life began as a student apprentice at Rolls Royce Aero Engines in Derby. I have always been interested in engineering and ran my own engineering business in Derbyshire for 25 years until I retired.

My workshop is divided into separate woodwork and metalwork sections, both fully equipped with a range of machine and hand tools, including welding and heat treatment, enabling me to be completely independent.

I am using my experience of wood and metalwork to develop a range of custom-designed tools and workshop equipment, specifically for the furniture designer/ maker, to address shortcomings I have experienced myself in some commercial offerings.

Custom Designed Workshop Equipment for Furniture Makers

Design & Prototype Multi-Mode Furniture-Makers Bench

Makers will be familiar with the “MFT” or multi-function table which has been around in various forms for a while.

Our Multi-Mode Furniture-Makers Bench take this concept to a new level with a series of innovative and effective developments, based on our own experience as makers

Design & Prototype Router-Track Adapter

In our shop we use Dewalt® tracks and saws and both Dewalt® and Festool® routers.

In order to use the Festool® router on the Dewalt® track for housings etc we manufacture an adapter block in our engineering section. This attaches to both items, without any modification to the router or track carriage. The dimensions can be amended for different makes of equipment on request.

Image pending, awaiting European Design Registration

Design & Prototype Dowelling and Drilling Jig

At Design & Prototype we have designed and used a unique jig which will join boards at any mitre angle and handle dowels down to 4mm, which allows use on boards as thin as 8mm. For T-joints, the dowel size is selected by rotating an indexed turret, without the need for additional bushes. It uses a hinged design to match any angle and is self-securing to the workpiece, without clamps. All operations take place on a common centre line, simplifying setting out and minimising the width of the tool, allowing use nearer the edge of the component. It uses standard 14mm drill bushes of any size up to 10mm and requires only a portable electric drill to operate, making it low-cost, quick, easy and accurate to use.

In addition to dowel joints, the jig can be used for centring holes on the board edge, drilling holes a fixed distance from any edge and drilling close-pitched holes in preparation for

morticing.

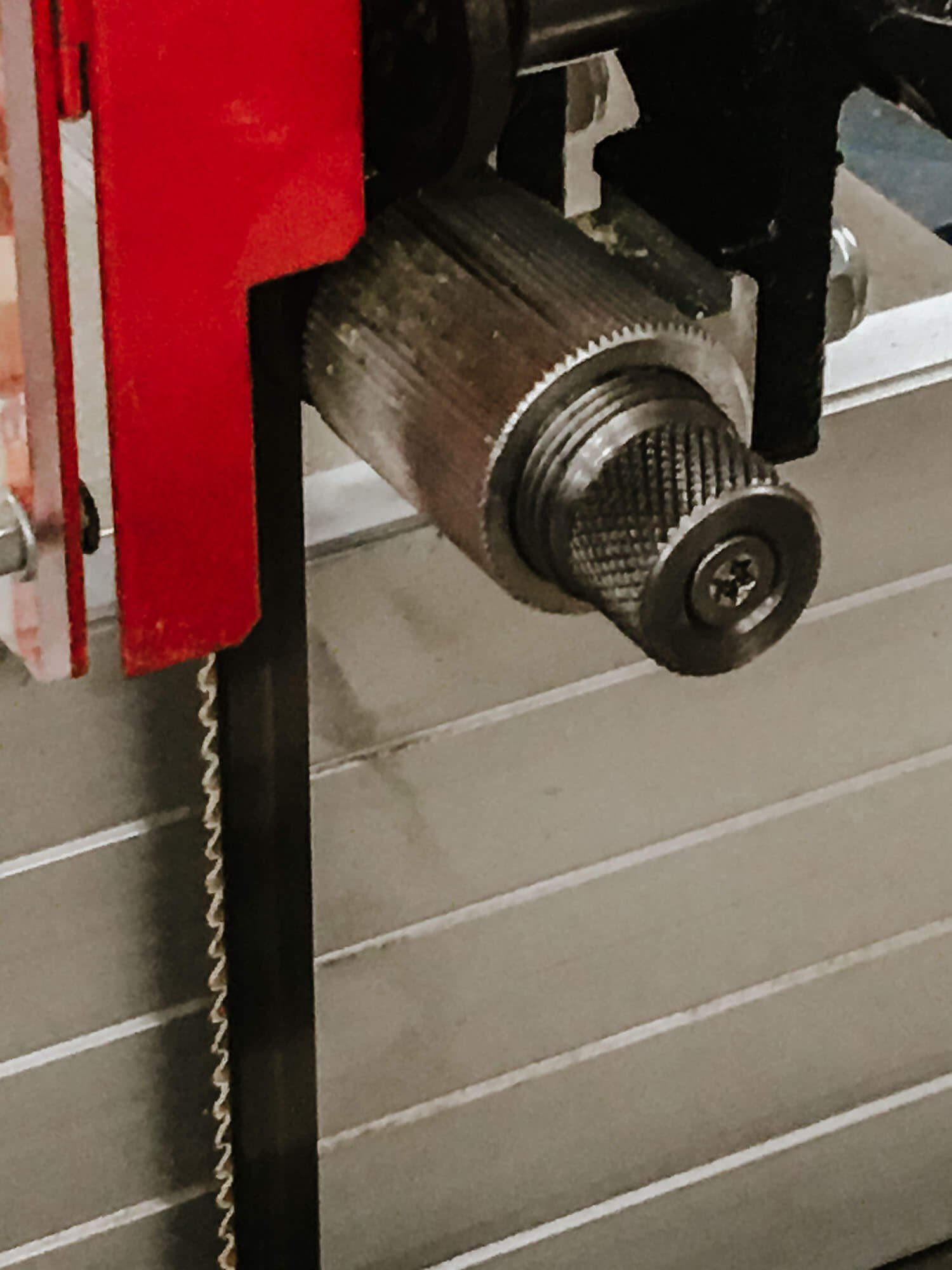

Bandsaw Guide Upgrade

This type of guide frequently has problems with lubrication, resulting in seizure and damage,

Our Workshop Upgrade option refurbishes the guides and provides provision for easy lubrication in the future.

Existing guides are stripped and cleaned before an oil port is machined in the end cap. The cap is sealed with a stainless screw.

The guides are returned fully assembled and lubricated, ready for re-installation in the machine.